Alright – so today we’ve got the honor of introducing you to Ashley Parent. We think you’ll enjoy our conversation, we’ve shared it below.

Ashley, first a big thank you for taking the time to share your thoughts and insights with us today. I’m sure many of our readers will benefit from your wisdom, and one of the areas where we think your insight might be most helpful is related to imposter syndrome. Imposter syndrome is holding so many people back from reaching their true and highest potential and so we’d love to hear about your journey and how you overcame imposter syndrome.

Starting Point: Feeling Overwhelmed and Unsure

When I took over my father’s company, I was immediately faced with a tidal wave of emotions. The loss of my father was still raw, and I was stepping into a role that felt overwhelming. I had big shoes to fill but lacked the technical expertise I thought I needed to succeed in the manufacturing industry. Imposter syndrome crept in, whispering doubts into my mind. I questioned if I could truly lead a business in a field where I felt like an outsider.

Initial Struggles and Facing Challenges

The challenges were real. I didn’t have years of technical experience or an engineering degree to lean on. I had to make decisions about machining processes, customer relations, and business strategy while grappling with the steep learning curve of understanding the industry. Every meeting, every quote, and every machine breakdown felt like a test I wasn’t sure I could pass.

Taking the First Steps to Learn and Grow

But I couldn’t let my doubts define me—or the company my father had worked so hard to build. I decided to dig deep and take control of my learning journey. I threw myself into research, devouring technical manuals, watching hours of machining tutorials, and seeking out industry forums and communities where I could ask questions. I learned the capabilities of every machine in the shop, their maintenance needs, and how to optimize their output.

Finding Mentors and Building Confidence

I wasn’t afraid to admit what I didn’t know. I reached out to seasoned professionals for guidance and asked my team to explain processes in detail. With each new skill or piece of knowledge I gained, I began to see the bigger picture of how everything worked together. Slowly, my confidence grew—not because I suddenly knew everything, but because I realized I could figure things out.

Achieving Results and Pushing Forward

Within a year, I turned my uncertainty into momentum. I grew the company’s revenue significantly, cut costs, and began implementing processes that improved efficiency. What had once been a source of fear—my lack of experience—became a driver for innovation and curiosity. My fresh perspective allowed me to approach problems creatively, and my determination to learn inspired my team to push themselves as well.

A Lifelong Commitment to Learning

Even now, I remind myself that growth is a continuous process. I stay up-to-date with industry trends, invest in training, and attend events where I can connect with other professionals. I also work to pass on what I’ve learned, mentoring others who might feel out of place in this industry—especially women like me, who might hesitate to step into the world of machining and manufacturing.

Closing with Reflection

Taking over my father’s company wasn’t just about learning the technical aspects of the business. It was about proving to myself that I could rise to the occasion, no matter how daunting it felt. Imposter syndrome didn’t disappear overnight, but I’ve learned that courage isn’t the absence of fear—it’s the determination to keep moving forward in spite of it. Every day, I remind myself of how far I’ve come and how much more there is to learn—and that excites me.

Appreciate the insights and wisdom. Before we dig deeper and ask you about the skills that matter and more, maybe you can tell our readers about yourself?

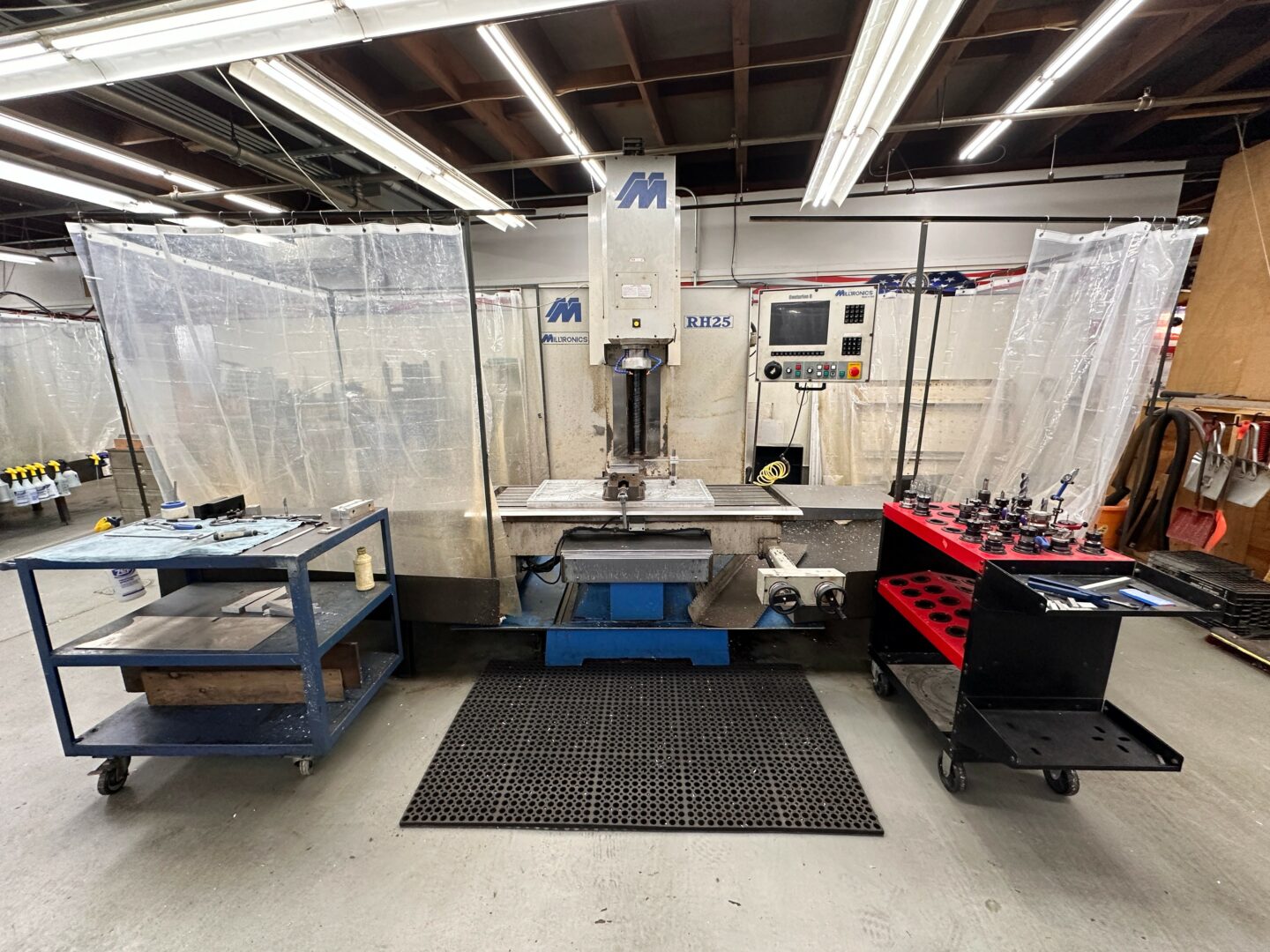

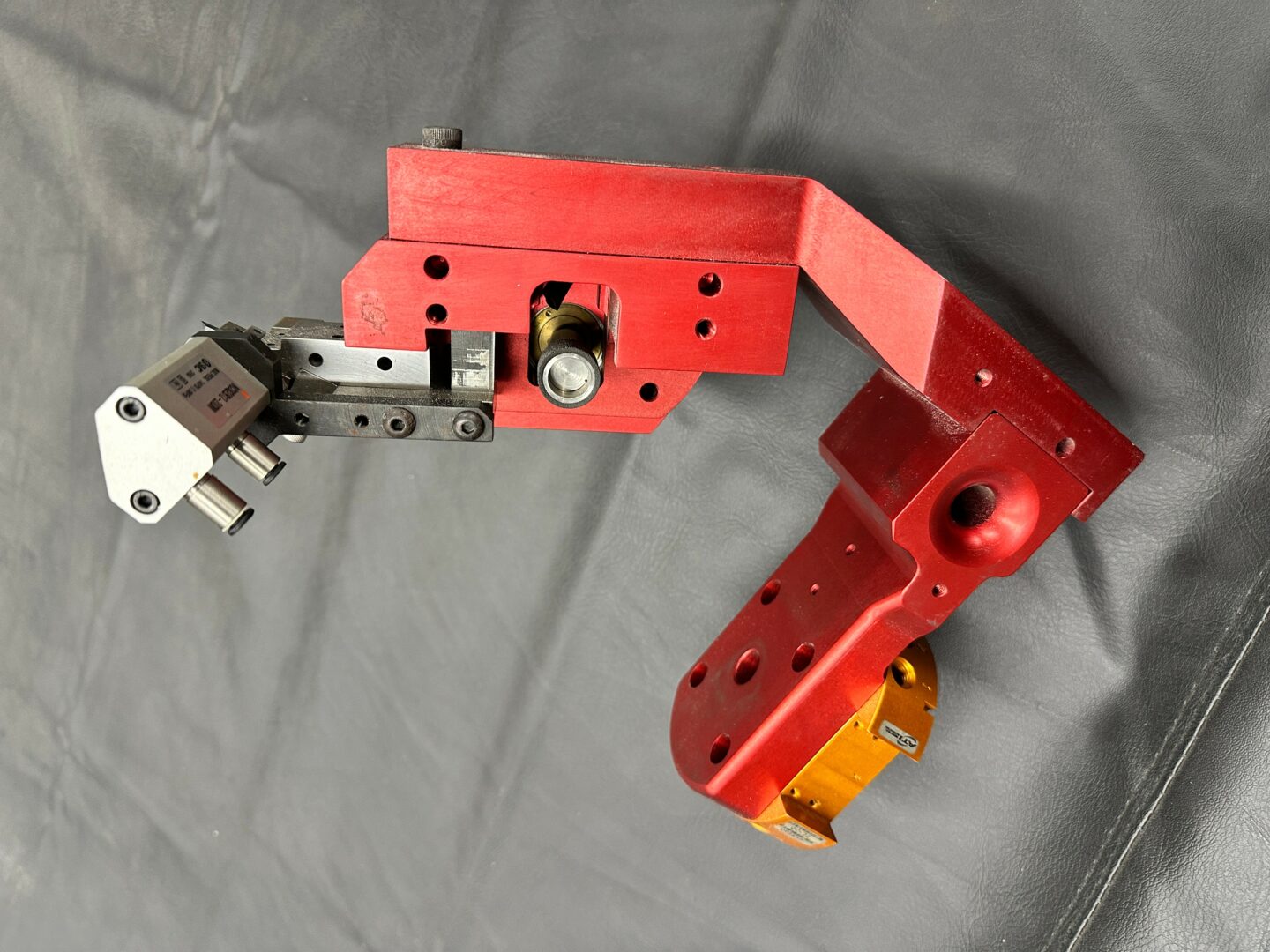

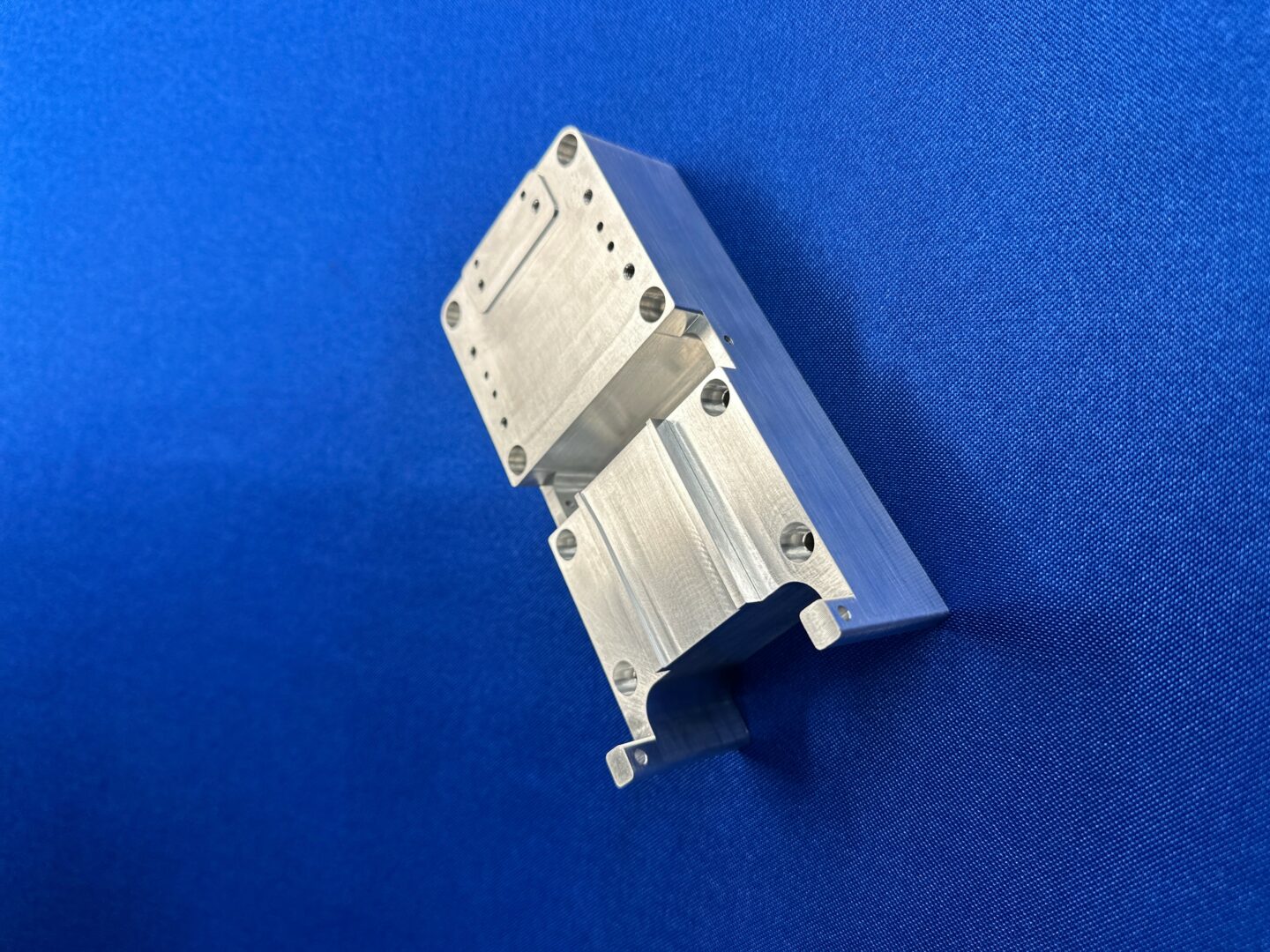

I’m Ashley, and I own and operate Mills Machine Works, a family-run prototype-to-short-run production machine shop. We specialize in precision manufacturing, collaborating with a diverse range of industries to bring ideas to life through high-quality machining solutions. What makes our work exciting is the constant challenge of solving complex problems and being a part of creating something tangible—from a concept to a fully realized product.

What sets Mills Machine Works apart is our commitment to precision, innovation, and personal touch. As a small, family-owned business, every project we take on has a direct impact on us. We take pride in delivering exceptional quality while fostering strong client relationships. Whether it’s creating a single prototype or managing a short production run, we’re dedicated to exceeding expectations.

Carrying on my father’s legacy is deeply meaningful to me. When I took over the company, I faced significant challenges, but those experiences ignited a passion for learning and growth. I worked hard to immerse myself in the industry, mastering the skills and knowledge needed to run a successful machine shop. Today, that passion drives me to continuously improve our operations and expand our capabilities.

One exciting development for Mills Machine Works is our collaboration with Paperless Parts, a platform designed to enhance quoting speed and accuracy. By integrating their tools into our workflow, we’re able to deliver quotes faster and with greater precision, ensuring our clients receive timely and reliable service. This upgrade allows us to focus even more on what we do best—producing high-quality machined components.

Looking ahead, we’re focused on optimizing our processes and taking on more complex projects, pushing the boundaries of what our small shop can achieve. Our dedication to innovation and quality is at the heart of everything we do, and I’m thrilled to see where this journey takes us.

At Mills Machine Works, we believe that every project matters. Thank you for giving me the opportunity to share our story, and I look forward to continuing to deliver exceptional service and solutions to our clients.

If you had to pick three qualities that are most important to develop, which three would you say matter most?

1. Resilience

Resilience has been a cornerstone of my journey. Taking over a business—especially in a technical, male-dominated field like manufacturing—came with its fair share of challenges. From learning the industry on the fly to weathering financial setbacks, resilience kept me moving forward. The ability to face obstacles head-on, adapt, and keep going despite setbacks is something I believe everyone can cultivate.

Advice: Resilience comes from mindset and practice. Start by reframing failures as opportunities to learn and grow. Surround yourself with supportive people who can remind you of your strengths when you feel discouraged. Lastly, celebrate small victories—they build the momentum to tackle bigger challenges.

2. Willingness to Learn

When I stepped into my role, I knew I didn’t have all the answers. But I was willing to dig deep, ask questions, and absorb knowledge from any source available—whether it was technical manuals, tutorials, or my team. That hunger for learning not only helped me gain the expertise I needed but also showed my team that I was serious about the work we do.

Advice: Stay curious and never stop learning. Ask questions, even if you feel vulnerable doing so—it’s better to admit what you don’t know than to pretend you know everything. Invest in resources like books, courses, or mentorship opportunities, and don’t shy away from rolling up your sleeves and learning hands-on.

3. Strong Communication and Relationship-Building Skills

Manufacturing is as much about relationships as it is about machines. Clear communication with clients and my team has been critical in building trust and delivering results. Strong relationships have not only helped me secure work but have also provided me with a network of support and advice.

Advice: Practice listening actively and asking thoughtful questions. Building genuine connections starts with showing interest in the people you’re working with. Be transparent and clear in your communication—whether you’re discussing expectations with a client or troubleshooting an issue with your team. Relationships take time to develop, so prioritize trust and follow through on your commitments.

Closing Reflection:

Looking back, these qualities didn’t come overnight—they were developed through trial, error, and a willingness to grow. My advice to anyone early in their journey is to be patient with yourself and take one step at a time. Trust that you’re capable of learning, adapting, and building the skills you need to succeed. And most importantly, don’t let fear of failure hold you back—every challenge is an opportunity to grow.

What is the number one obstacle or challenge you are currently facing and what are you doing to try to resolve or overcome this challenge?

One of the biggest challenges we’ve faced at Mills Machine Works began around the time of my father’s passing. Many of his key buyers and engineers, who had been integral to our business for years, started to retire, taking a significant portion of our business with them. We were forced to quickly pivot and find ways to reach new customers, which brought its own set of challenges.

One of the most difficult aspects of this shift has been adapting to how younger engineers and buyers prefer to communicate. Unlike before, when relationships were built through phone calls and in-person meetings, many now prefer email or other digital methods. While this allows for efficiency, it also makes it harder to establish the strong, personal relationships that have always been the foundation of Mills Machine Works.

To tackle this challenge, we’ve focused on adapting our communication strategies while staying true to our relationship-focused values. We’ve worked on improving our digital presence, creating clear and engaging emails, and using tools like Paperless Parts to make quoting fast and seamless. This helps us meet buyers where they’re comfortable while still showing the care and attention that sets us apart.

At the same time, we’re finding small ways to add a personal touch. Whether it’s a quick video walkthrough of a project, a handwritten thank-you note, or following up with thoughtful questions, we’re finding ways to stand out in a digital-first world.

This challenge has taught us the importance of flexibility and innovation. While the way we build relationships may look different now, the values my father instilled—care, quality, and connection—remain at the heart of everything we do. And as we continue to grow, we’re finding creative ways to blend those values with modern tools to build new partnerships and ensure a bright future for Mills Machine Works.

Contact Info:

- Website: https://www.millsmachineworks.com

- Instagram: @millsmachineworks

- Linkedin: https://www.linkedin.com/in/ashleymparent/

so if you or someone you know deserves recognition please let us know here.