We caught up with the brilliant and insightful Ryan Shelton a few weeks ago and have shared our conversation below.

Hi Ryan, so excited to have you with us today, particularly to get your insight on a topic that comes up constantly in the community – overcoming creativity blocks. Any thoughts you can share with us?

Once in a blue moon if I’m unable to advance on the project at hand I usually find myself watching old documentaries relatable to the project at hand. I’m a rather big fan of the early 20th century science and engineering films. That seems to give the inspiration to help drive me forward.

Let’s take a small detour – maybe you can share a bit about yourself before we dive back into some of the other questions we had for you?

I’ve always thought of myself as someone who does things just a little different.

I’ll certainly educate myself to the fullest extent of my ability on the fundamentals of what I’m wanting to accomplish but once I have a firm grasp of what and how to go about starting, working, reworking and final completion of a project, I implement 3D printing and years of self-taught technical skills to overcome most of the roadblocks that are associated with advancing in the aerospace industry.

Around April-May of 2023 I finally decided to give High power rocketry a try. I started learning all about the process from level 1-3.

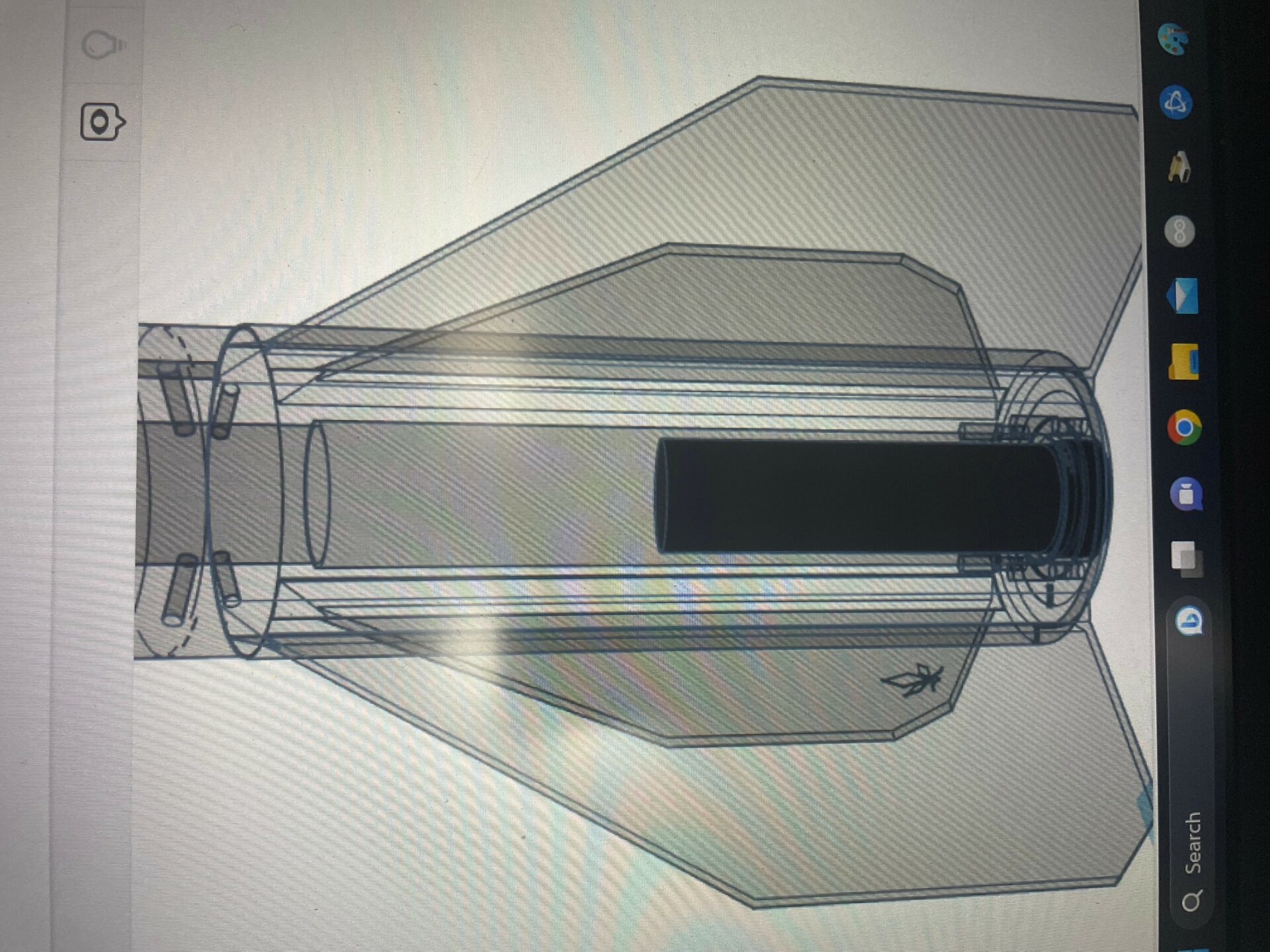

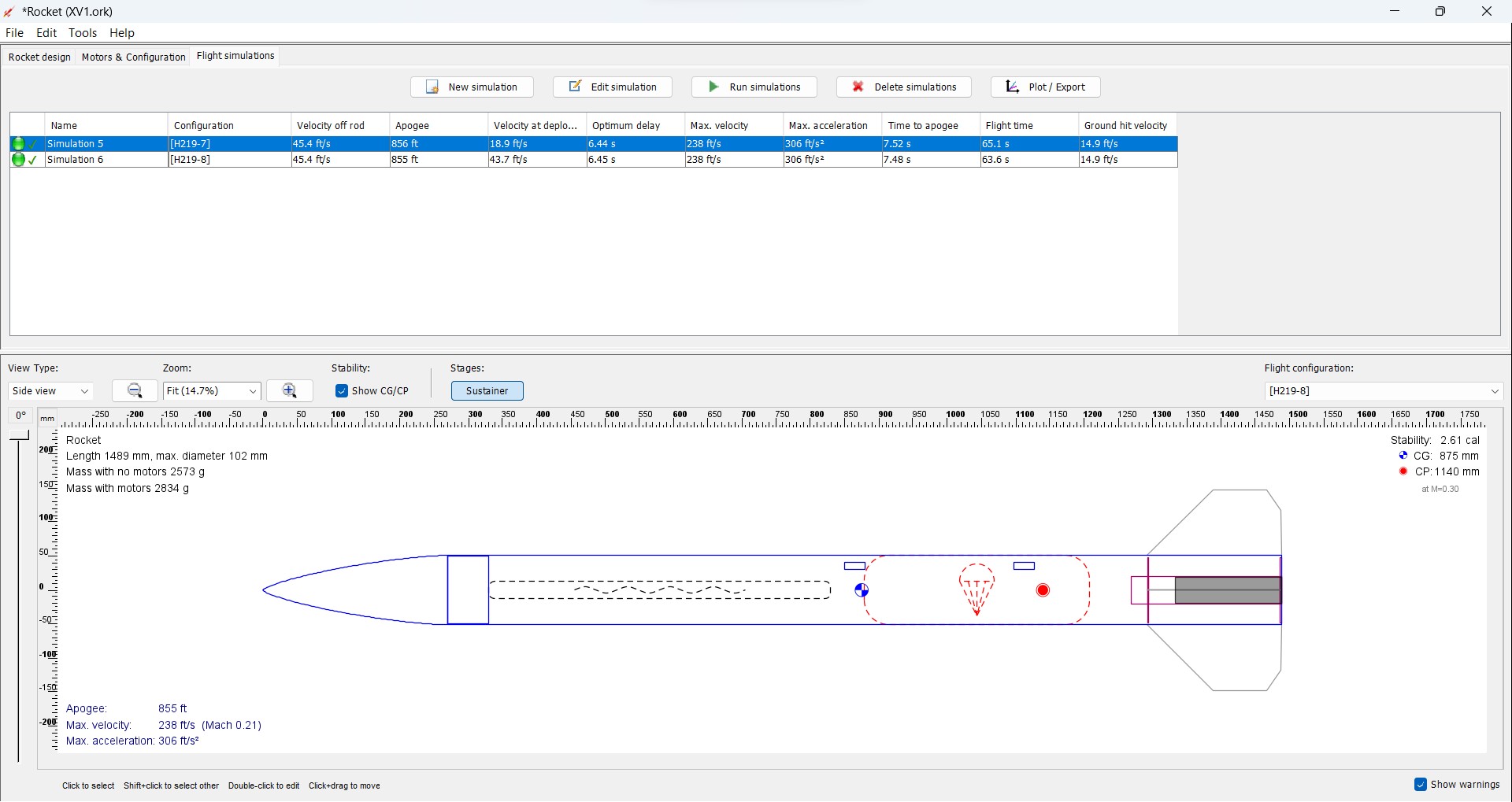

I did as much research as I could and once I felt like I understood what was needed I got to work on printing the largest rocket ever to date. STRATUS-SV3. A level one rocket designed to fly with H powered motors and secure the level one certification test flight.

The rocket standing at 5 feet tall and 4 inches wide at the body tube, along with being over 3 and a half pounds, was huge when compared to any other rocket I had previously engineered. After several test prints and many redesigns, the final rocket was ready to take flight.

The day had come for my certification, and I must admit while I was hoping for the best, I knew this was technically a test flight with an untested prototype rocket.

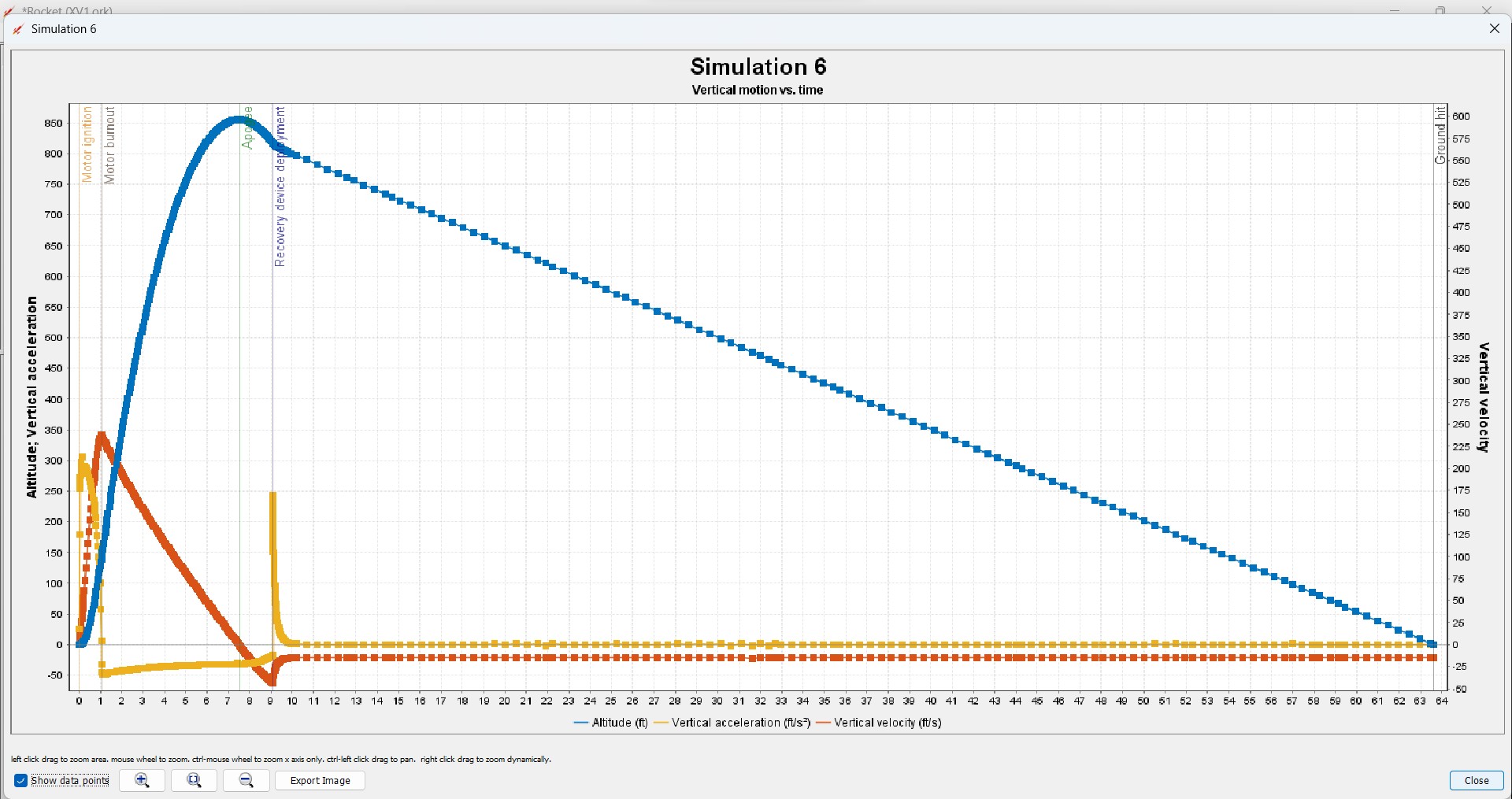

Once I had the H219 blue thunder motor delay set and installed into the rocket I walked it out to the rail. Two others were out there that day. Both were level 1 NAR rocketeers to witness and certify my flight if said flight was successful. Once everything was set and ready I did the countdown. And once I had pressed the launch button… A mighty and heavy roar emitted from the rocket, and it shot straighter and smoother than I could have ever hoped or imagined for. Once at apogee the rocket tilted slightly and exactly on top the parachute was ejected and deployed flawlessly. The descent was smooth and with little to no wind or breeze, the rocket came down a mere 10 feet from its launch area.

Once the launch site was clear I walked over to retrieve the rocket. And upon walking up to the rocket my heart dropped. The fin-can had separated from the body tube. It was a rare moment for me personally to be feeling not only the excitement and accomplishment of flying my first high power rocket, I was also dealt a failed level one attempt.

While I wasn’t a hundred percent upset at the failed certification because rarely do first attempts at anything in life end in success, I was more in disbelief that I didn’t make the main connection point of the rocket able to handle the simple task of withstanding the recovery landing.

But not long after I came to a realization. This is something, while not entirely new to me, was still something I had little experience in. I was slightly overconfident in my abilities when it came to actually prepping, launching, flying and recovering high power rockets.

I knew that this meant one thing.. Back to the drawing board. I redesigned the rockets coupler section and rebuilt the entire rocket in under 5 days. I was proving my turn around times from failed flight to ready for a second try was incredibly quick thanks to my printers and my previous test flight experience.

In October of 2023 I attempted a second certification flight. The local NAR group Kingman rocketeers were out that day holding their monthly launch. Another individual was out there also attempting a level one cert flight.

I prepped the motor, loaded the rocket and walked it to the rail.

I decided it was best to let others fly first so I wasn’t the show starter.

The other person who was certifying went first and had a really smooth launch, flight and recovery.

He passed.

I was next to fly and with a count down, the button was pushed and just as before the SV3 roared to life, and quickly and very straightly ascended to a guesstimated altitude of 900 feet. The ejection charge went off at the exact moment it should and as the rocket began its decent, me and everyone noticed the parachute had gotten tangled around the shock-cord and the rocket was in a free fall.

While I knew the likely hood of the survivability was near zero, I braced for the impact as it came falling down and witnessed something I would have never imagined… Once the field was clear I walked over to retrieve and inspect the cause of the failed deployment.

What I saw proved one thing. Sheltech made an excellent quality rocket. The only damage was a cleanly broken off fin. I searched for the broken piece but to no avail. If I had found it, it would have beautifully epoxied back together for another flight.

The rest of the rocket didn’t even have a scratch aside for dirt on it from landing.

It was a personal win for me and a major boost in my 3D aerospace career.

The gentlemen with the NAR said they had never seen a rocket fly so straight and smooth that wasn’t a well-known kit.

I was happy to explain everything I could about who and what I do and they all agreed I have the rocket building down, now I need to get more time flying under my belt. I assured them I would be back for a 3rd attempt in the spring of 2024.

The roadblock… Like most projects that involves aerospace, if you’re not qualified, you can’t do certain things. Certification was my means of acquiring larger motors for bigger and higher altitude rockets. I was making decent strides in perfecting the recovery apparatus but without test flights and real world flying to learn off of and a passion to continue my work… I knew I had to figure out a way to safely and legally fly larger rockets without the say of a governing body.

While I highly suggest and encourage individuals who want to pursue rocketry to follow any and ALL NAR rules and guidelines, when you have a goal, and something is preventing your from furthering your progress towards said goal, regardless of what that block may be… You either stop and wait for the moment to come to you, or you make the moment happen.

About one week ago I began working on an old project of mine. It’s called rocket Kandy. Not to be confused with edible candy. But the mixture of potassium nitrate and sugar used as propellant in small to large rockets before the days of store/shelf bought motors.

While I just started up on the KN03 and sugar project again I have been researching it for many years and have the knowledge to safely pursue building my own motors. The current recipe in one-gram pieces can burn for over seven seconds.

Once more testing is done to find out how much thrust the formulation of 70/30 produces, we hope to be flying our rockets on our own motors early 2024.

That is what separates ShelTech LLC apart from the others. And I love that.

There is so much advice out there about all the different skills and qualities folks need to develop in order to succeed in today’s highly competitive environment and often it can feel overwhelming. So, if we had to break it down to just the three that matter most, which three skills or qualities would you focus on?

The number one quality I cannot stress enough on is self-confidence. While it is possible to be overconfident, not enough is just as bad.

When you get/are good at something, stick with it.

Never let anything stand in front of you and your goals.

What has been your biggest area of growth or improvement in the past 12 months?

In house manufacturing/sourcing. While we have always been making our own products here in Arizona, we didn’t always have the means to make out own motors nor electronics until recently.

I’m very proud at the fact our reliance on outside sources is becoming smaller each year.

Contact Info:

- Facebook: https://www.facebook.com/ShelTechLLC

- Youtube: https://www.youtube.com/channel/UCfZLa4Rzsk6OIxHxiPowl9Q

Image Credits

Ryan Shelton.